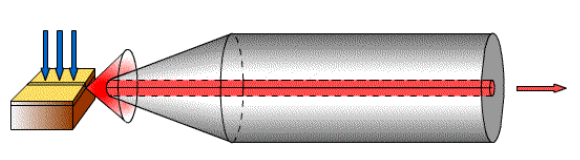

Optical fiber lens, also known as optical fiber lens or lens fiber, is made by processing the tip of the fiber into the shape of a certain lens. It is used to change the optical path or transform the optical mode in optical system.

Different fields require for different fiber lenses. In terms of the shape of lenses, they can be divided into inclined plane, wedge (double inclined plane, or four inclined plane), sphere, conical, etc., as shown in picture below. Moreover, optical fiber lens can also be divided into single fiber lens and fiber lens combination based on the form of fiber lens. This paper mainly introduces the principle and application of different types of fiber lenses.

|

|

|

|

|

|

( figure1) | ||

Inclined plane fiber lens can be 6° ~ 10° inclined and 40° ~ 50° or more inclined. 6° ~ 10° inclined fiber lens is used to prevent interference or damage caused by reflected light returning to the optical path; 40° ~ 50° or more inclined lensed fiber arrays can change the light path or even form a total reflection in the light path, and they can also increase the light area of the fiber, so that more light can enter into the fiber. As for this kind of fiber lens, it is mainly used in optical fiber laser, optical fiber communication, traditional optics, and optical fiber sensing etc.

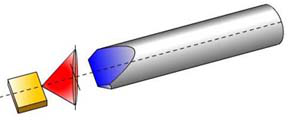

Combination of wedge-shaped lensed fiber are normally used for optical path coupling. Among them, there are micro cylindrical fiber lens made with wedge fiber lens front end, four-bevel fiber lens, and inclined wedge fiber lens, which are collectively called wedge fiber lens.

Most beam spot of LD is elliptic, and the ratio of the long and short axes of the ellipse is in direct proportion to the output power. Normally, the ratio is 3~5. it can be over 10 or even up to 50 for high-power LD. Obviously, such beam is difficult to be coupled into the optical fiber. In order to adapt to the shape of LD output beam, wedge-shaped fiber lens can be used by facing the two large wedges to the large divergence Angle of LD, so as to increase the efficiency of LD coupling into the optical fiber.

AR coating is needed for ordinary wedge lens to minimize the reflected light, but for wedge fiber lens, because of the special geometry, a refraction angle is formed between the LD and the fiber lens, therefore further avoid the influence of reflected light of LD and eliminate the noise caused by the reflected light as well. Compared with ordinary wedge - shaped optical fiber lens plating AR coating process, it reduced the cost and the instability caused by poor controlling of coating process.

(figure2)

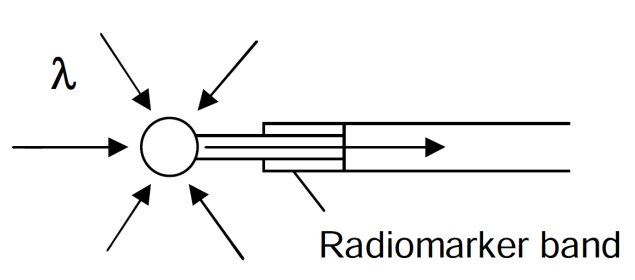

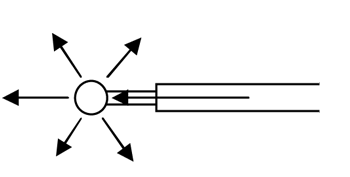

The application of spherical fiber lens can be used in many fields, such as optical coupling, biology field, medical science, sensing and so on. Re-fabricating of a bevel lens on a spherical fiber lens can be applied to OCT, an imaging diagnostic technique that has been developing rapidly in recent years. ( figure 3)

(figure 3)

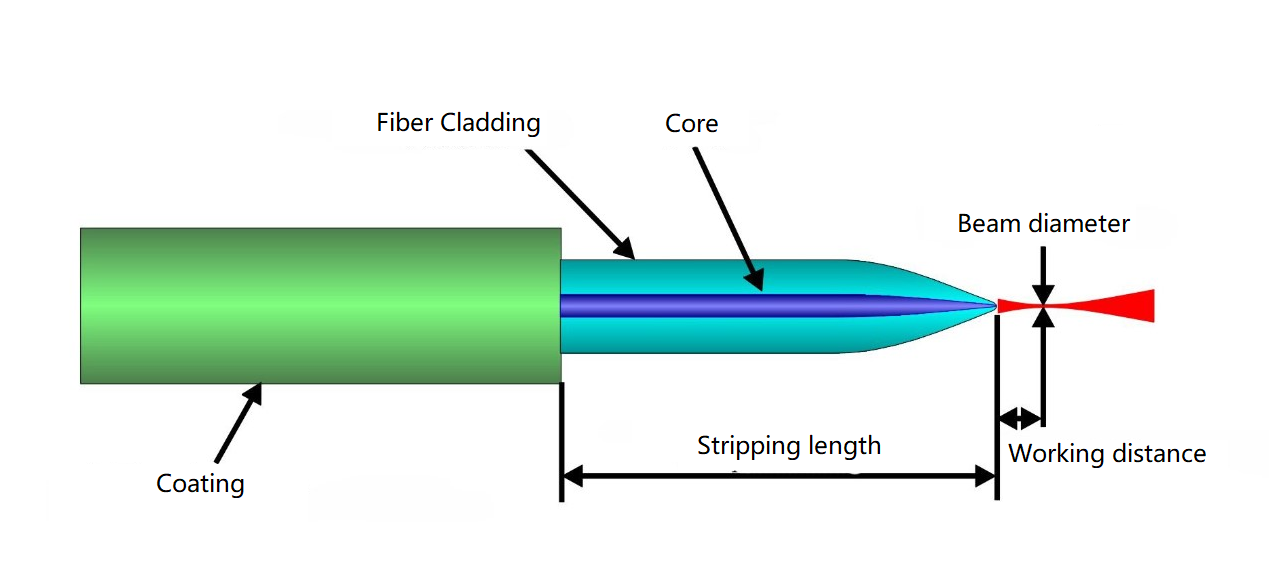

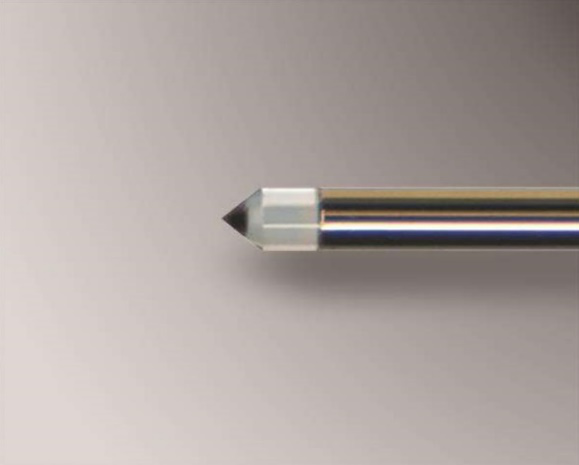

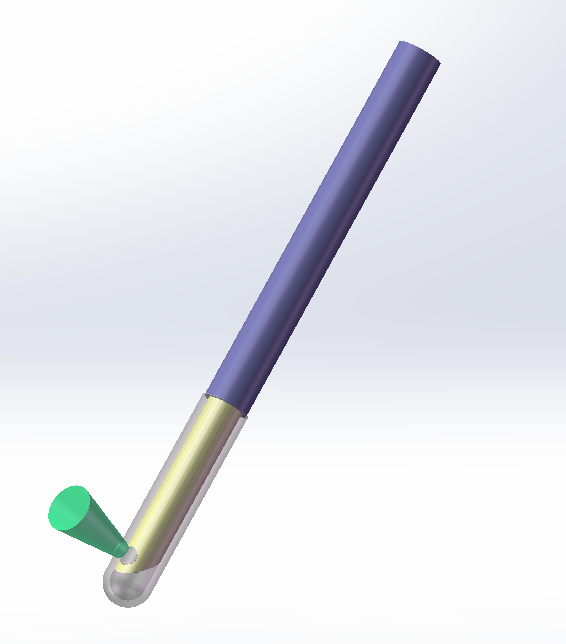

Because the conical fiber lens can achieve the purpose of expanding the numerical aperture of the fiber and increasing the optical receiving capacity, conical fiber lens is very suitable for coupling with LD, DFB, SLD laser or VCSEL whose output beam cross section is round or approximately round. High-precision conical fiber lenses are also used in medical laser microsurgery systems and micro lighting systems. (figure 4)

(figure 4)

Zhongshan MEISU has first-class optical fiber lens processing technology, and we have also independently developed a complete set of optical fiber lens grinding equipment, which can produce various shapes of optical fiber lens with low cost and high precision. With the help of the grinding equipment, we can also test the optical spot, far-field and other parameters of the lens. Different processing such as metallization, anti-plating (AR) coating, terminating with connector can also be added to the lens, besides, multiple fiber lenses can be assembled into fiber lens array.

MEISU specialized in lensed fiber for the commercial and research market place including optical fiber lens systems and telecommunication applications. MEISU fiber lens are high coupling performance components for improving lensed fiber coupling.

Optical fiber lens can be applied in optical fiber communication, fiber laser, industrial laser system, medical laser system, etc. For different application occasions, MEISU developed optical fiber lens with different structure and shape, some typical application examples are listed in the pictures below:

MFD lens fiber for Silicon chip coupling

Conical fiber Metallized lens fiber

Side emitting medical laser fiber

PICs From http://www.53179.net/a/yule/364.html